Sakai Takayuki Gintan(銀鍛, Silver-Forge) is a pretty well positioned lineup in our stainless single bevel range. It is a step up from the more basic lines like the Inox series in both material and fit&finish. Knives in this line feature beautifully hand engraved line names, refined polishing on the bevel and a different styling that originated from its birthplace. This line is a good stepping stone from entry level single bevel blades and these knives would comfortably find themselves a place in high end sushi restaurants while being easy to look after.

For single bevel knives, this is about the lowest price you can get for a Ginsan steel knife, Ginsan is a unique steel in the world of cutlery steels and it has a strong connection with single bevel knives. Single bevel knives now, if you would like to do it right, are still forged individually to achieve the right Ni-Mai forge welding and blade profile, and to sharpen them, you would need to remove more material on the Kiriha(primary bevel). This means blacksmiths need a steel that is easy to forge and chefs prefer a steel that is easy to sharpen, thus most single bevel knives are made with carbon steel.

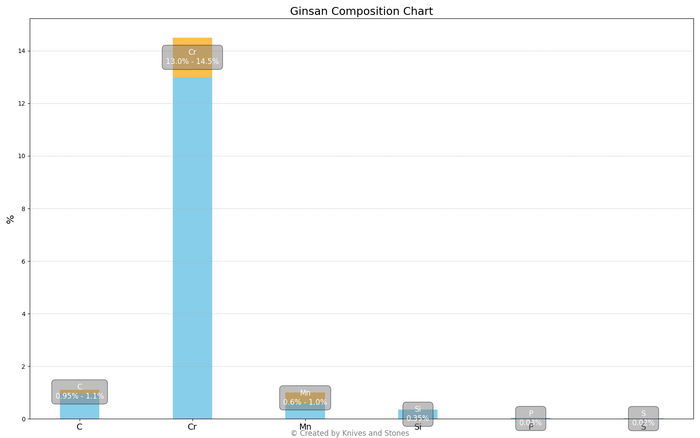

Stainless steel is characterized by the chromium addition that gives steel stainlessness and wear resistance(through chromium carbides), but they often introduce other alloys to further increase the wear resistance. The additional carbides makes stainless steel hard to sharpen and hard forge, thus Hitachi decided to make a very “pure” stainless steel that only has chromium addition for making low maintenance single bevel knives, which results in the Ginsan steel.

This specialty steel has limited use as its relatively low wear resistance makes it hard to compete in other applications, but it has become the standard stainless steel to be used in single bevel knives all the way to the very high end ones. The reason that Gintan still comes at a more premium price while being a more “budget” Ginsan steel knife is partially due to the forged nature of them, although being optimised, Ginsan’s forging and heat treading is still harder to perform than regular carbon steel.

For experienced eyes, the Gintan series features a profile that is slightly different from the typical Sakai-made pieces. The Deba of the Gintan series have a curved spine that extends all the way to the tang while the Sakai ones often straighten out behind the tip, Yanagiba have a similar feature and they all have a taller/wider profile than other series that Takayuki offers. According to our suppliers, the Gintan series are manufactured in Tosa, and if you look at other Tosa-made single bevel knives like Hatsukokoro’s Shirasagi series, it is not hard to see some kind of similarity between the two lines. These details and regional features are fascinating to look at and explore.

The broader profile Yanagiba in the Gintan line is a compelling item in my mind, they feel quite firm in the hand due to the additional material, and the taller blade can give you a more confident slice. While they are nowhere near “budget”, the prices are still very competitive when considering what is being offered. If you are a chef looking for an intermediate range Yanagiba that would fit the status of your sushi restaurant, this would be a good line to switch to while keeping the maintenance low. If you are a Sushi enthusiast looking for a home single bevel knife, these stainlessness, fit and finish and beautiful engraved blade can easily find a place in your collection too.