Takamura is a name that is certainly influential in the industry, being one of the oldest existing knifemaking companies in Echizen city, this company was a pioneer in the front of technological advancement and knifemaking skills. Their knives are often regarded as the best in performance, and their higher end items have such an attractive design that many seek to get one even with a price that is beyond reasonable.

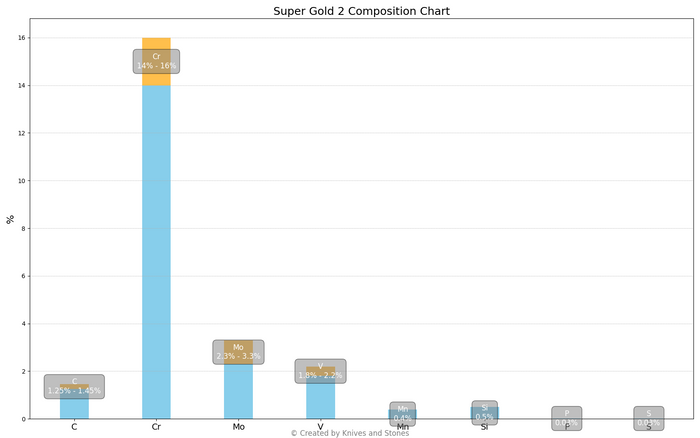

In 1945, the then 35-year-old first generation founded the company after 23 years of training in the industry. The second generation blacksmith was very intrigued with the idea of high performance stainless steel, and after four years of research, Takamura finally entered the production of forged stainless steel knives in 1958, which is very early for this industry that was still predominantly using carbon steel. By 1982, Takamura was already using clad power tool steel for kitchen knives, which was really pioneering considering the first powder tool steel only became commercially available in 1970. With the introduction of power stainless steel in 1985, forged powder stainless steel damascus in 1987 and even an attempt of Titanium knife in 1999. Takamura continuously writes more and more legends in its history.

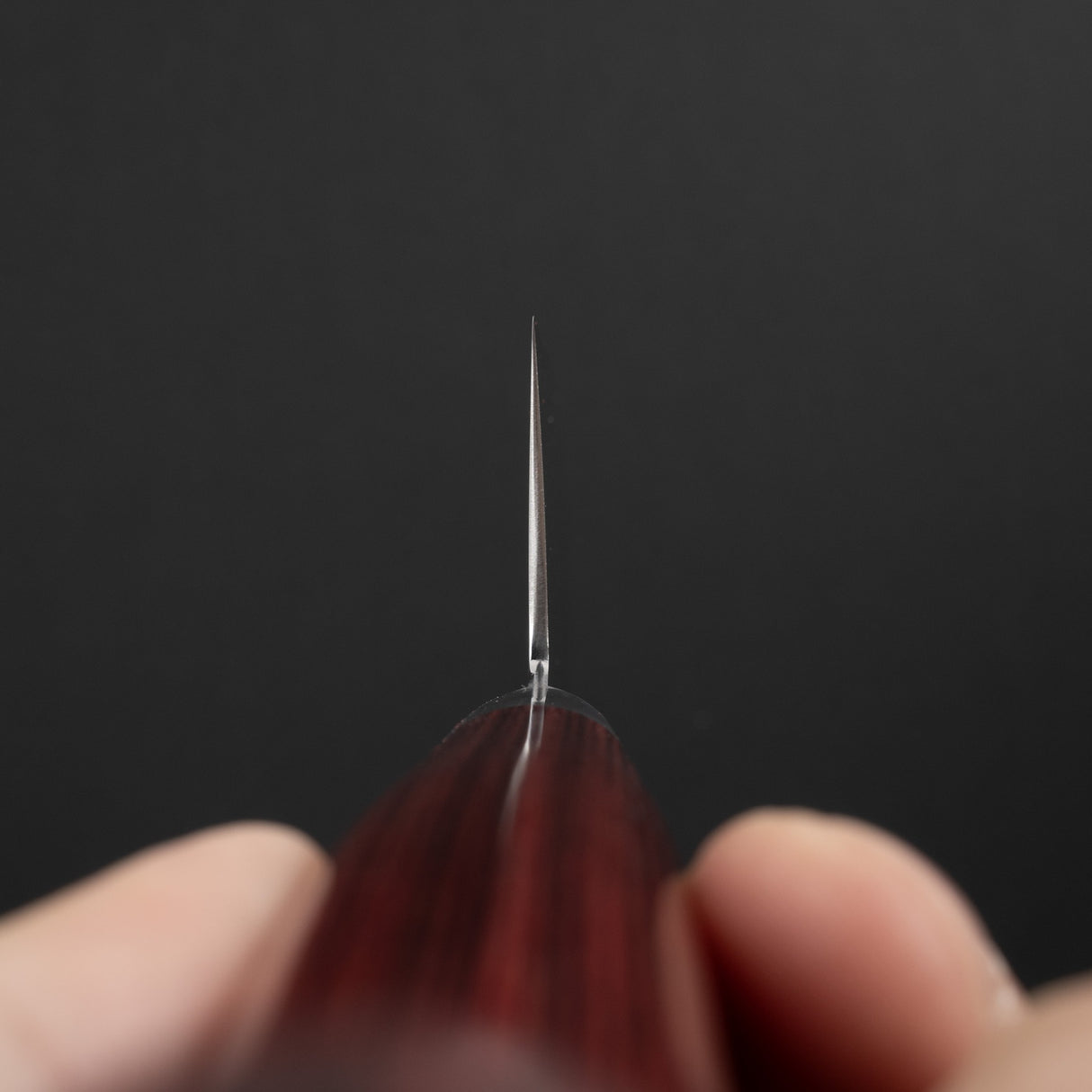

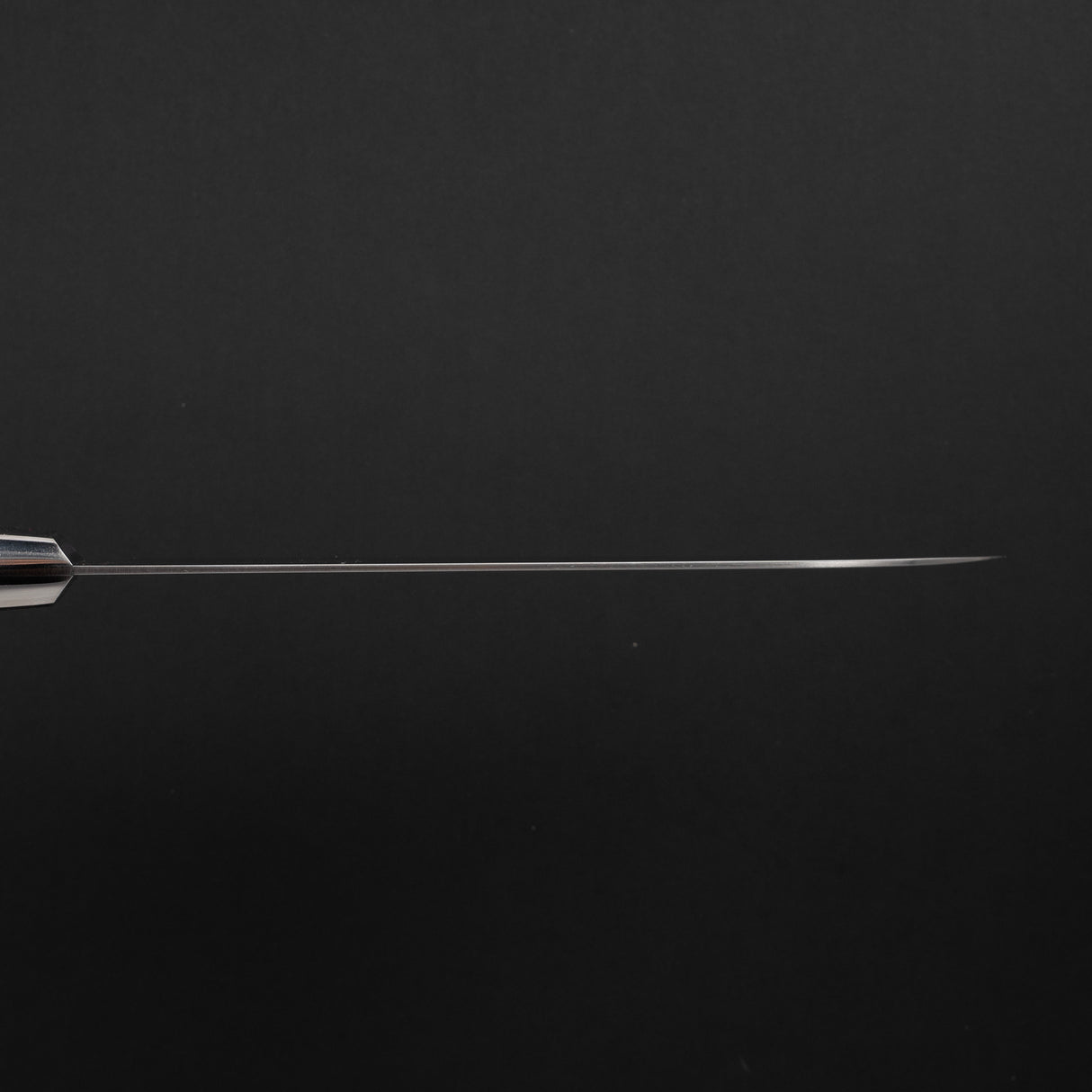

Their excellence is not limited to the steel and technology, many of the chef and knife users consider Takamura’s knives as the best cutting knives. For example, their best selling and best known SG2 series is super thin while having a really pleasing convex, paired with the brushed finish, the minimal resistance can be achieved by reducing both the wedging and sticking. Being super thin throughout the blade, it is one of the original “laser” knives you could get out there. This performance heavily influenced other sharpeners, Kei Kobayashi said he bought a Takamura privately to study it when he was learning as a sharpener as he was impressed how well it cuts, I believe the impact of Takamura is quite beyond that.

Aside from the highly functional blades, Takamura also produced some of the most sought after artistic knives. The Uchigumo and Uchigumo Hana with their textured Damascus and polished integral bolster have given the knife a very unique look. Takamura was able to come up with an impressive design like that all the way back in 2003, when Japanese kitchen knives weren’t really a thing outside of Japan.

I really think Takamura is a representative brand for knifemaking in Echizen, it combines extensive history with innovation in the technological front. Makers in Echizen embrace newer technologies, material and toolings but inherit the core value of producing high quality and highly functional knives, and historically speaking, Takamura was one of the companies that was paving the way in this path.