Tsunehisa | SKU:

TNHS-GIN3-DB150

Tsunehisa Ginsan Deba 150mm

Regular price

$299.95

Unit price

/

Unavailable

Tsunehisa Ginsan Deba 150mm is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Detailed Specifications

| Line | Tsunehisa Ginsan Nashiji |

| Profile | Deba |

| Bevel Type | Single Bevel |

| Weight | 250 g | 8.8 oz |

| Edge Length | 152 mm | 5 63/64″ |

| Heel Height | 47 mm | 1 27/32″ |

| Width @ Spine | 7.3 mm | 9/32″ |

| Width @ Mid | 6.3 mm | 1/4″ |

| Width @ 1cm from Tip | 2.7 mm | 7/64″ |

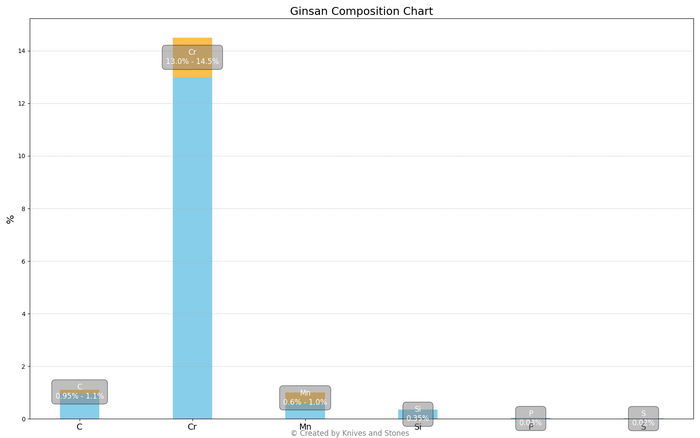

| Steel | Ginsan / Silver #3 | Stainless |

| Blade Construction | Sanmai - Stainless Clad |

| Hardness (HRC) | 60 - 62 |

| Surface Finish | Nashiji |

| Handle | Ho Wood Octagonal |

| Region | Fukuyama |

| Best for |

|

| Pros | Cons |

|

|

|

Care Instruction

- Don't cut hard things! Japanese knives are brittle so bone hacking is a NO NO!

- Wash with neutral detergent after use, and wipe dry;

- Please don't wash knife with dishwasher, it will damage the wood handle;

- Be careful not to leave the knife close to a heat source for a long time;

- It is a lot more dangerous to cut with a blunt knife than a sharp knife!

- It is best to sharpen a Japanese knife regularly on a waterstone.