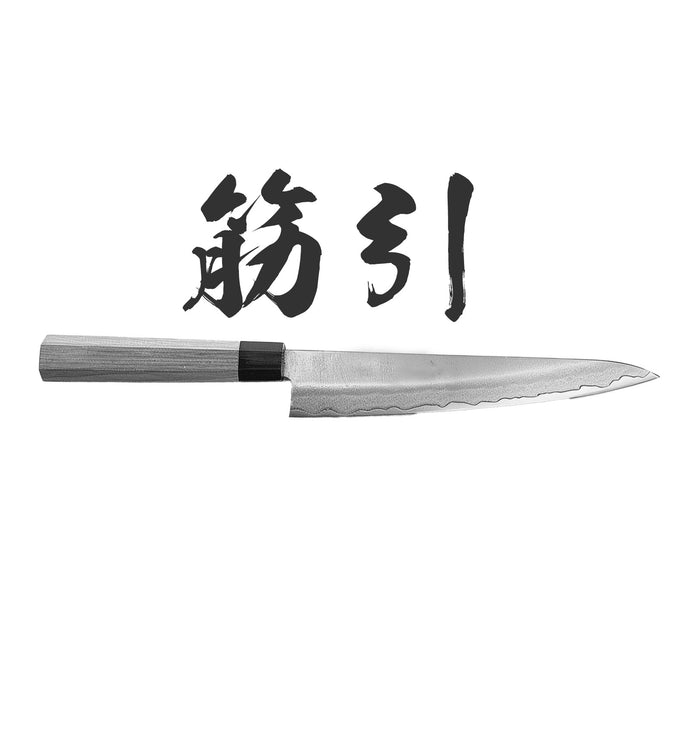

Sakai Takayuki Grand Chef SP Sujihiki 270mm

Sakai Takayuki Grand Chef SP Sujihiki 270mm is backordered and will ship as soon as it is back in stock.

Couldn't load pickup availability

Detailed Specifications

| Line | To Be Added - Stainless clad |

| Profile | Sujihiki / Slicer |

| Bevel Type | Double Bevel |

| Weight | 143 g 5.04 oz |

| Edge Length | 269 mm .10.59 inch |

| Heel Height | 32 mm .1.26 inch |

| Width @ Spine | 2.0 mm 0.08 inch |

| Width @ Mid | 1.6 mm 0.06 inch |

| Width @ 1cm from Tip | 0.7 mm 0.03 inch |

| Steel | Swedish Steel | Stainless |

| Blade Construction | To Be Added |

| Hardness (HRC) | 58 - 60 |

| Surface Finish | To Be Added |

| Handle | Western Pakka Wood with Bolster |

| Best for |

|

The Sakai Takayuki Grand Chef SP Sujihiki 270 mm is a premium slicer crafted in Sakai, Japan — a region celebrated for centuries of knife-making excellence. Forged from high-purity Swedish stainless steel and hardened to around HRC 58-60, this mono-steel blade offers superb edge retention, sharpness, and ease of maintenance.

The long, narrow profile and 50/50 double bevel allow for precise, effortless slicing of meats, fish, and vegetables. A key feature of the Grand Chef SP series is its hollow-ground blade face, designed to reduce surface friction and prevent food from sticking — ensuring each cut glides cleanly and smoothly.

Balanced with a comfortable Western-style handle (often POM resin or hardwood), the knife delivers both control and comfort in extended use. Combining outstanding steel, refined geometry, and Sakai craftsmanship, this sujihiki is ideal for professionals and enthusiasts who demand precision and performance in every slice.

Care Instruction

- Don't cut hard things! Japanese knives are brittle so bone hacking is a NO NO!

- Wash with neutral detergent after use, and wipe dry;

- Please don't wash knife with dishwasher, it will damage the wood handle;

- Be careful not to leave the knife close to a heat source for a long time;

- It is a lot more dangerous to cut with a blunt knife than a sharp knife!

- It is best to sharpen a Japanese knife regularly on a waterstone.